How to select a Plate Rolling Machine

How to Identify the Right Plate Rolling for Your Needs

- Right selection of Plate Rolling Machine for your need is depending up on the various factors like, your application, your production requirements and your budget.

Plate Rolling Machine Features Comparison

Mechanical Screw Type Plate Rolling Machine

|

|

Semi Hydraulic Without Pre Pinch

|

3 Roller Fully Hydraulic with Pre Pinch and NC

|

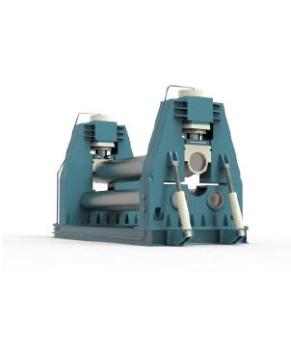

4 Roller Fully Hydraulic with Pre Pinch and NC

|

Contact Us

Inforce Engineering

19-20 Shree Ram Industrial Park, Ahemdabada Indore Highway, Village - Kuha, Ahmedabad, Gujarat - 382433, India

Call Us : View Mobile Number

E-mail : inforcemachine@gmail.com